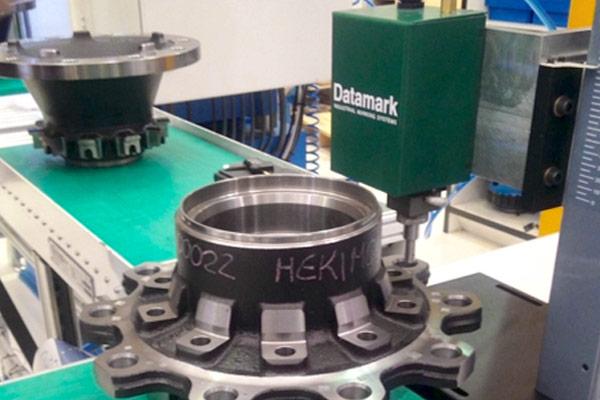

MP Integrated series dot peen markers are designed for easy integration into production lines and manufacturing cells. Each system includes a compact, yet powerful pneumatically actuated marking head that is easy to install in small or hard-to-reach areas; and a mountable full-color, industrial-grade touchscreen control panel running intuitive, fully featured marking software.

- Compact, lightweight design with robust, all-metal construction

- Powerful pneumatic marking head for high-speed (up to 12 characters per second), precise marking; capable of creating deep marks that remain readable after painting, galvanizing or blasting the part

- Cost effective; requires little maintenance

- 7" full-color touchscreen controller; operate either in standalone mode or receive marking data commands from a network system, PC or PLC

- Fully featured, intuitive DataMark™ marking software included with WYSIWYG interface; mark text, numbers, logos, Data Matrix codes and more

- Programmable marking speed, depth and dot density; for metals up to 62 Rc

- Interchangeable marking stylus for standard, fast and deep marking

- Automatic marking of serial numbers, dates, time and shift codes