Dapra can help you ensure that you are adhering to MIL-STD-130 when marking Department of Defense (DoD) components for clear, permanent identification and traceability.

A wide variety of parts and components are supplied to the DoD, and many legacy parts are currently stocked in DoD depots. This can range from fighter jet and tank components to parts for military vehicles, ammunitions, firearms and more.

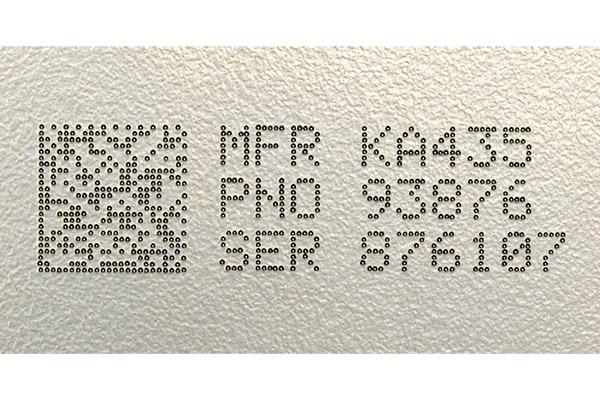

Data Matrix, a machine-readable code, is a standard for implementation of permanent, direct part marking (DPM) and part tracking programs. It can be utilized throughout the part life cycle, which includes manufacturing, supply chain and in-service operations. Many industries, including Aerospace, Automotive and Electronics, have already implemented machine-readable technologies based around Data Matrix codes. Most recently, the demand for this technology has been driven by the DoD (Department of Defense) and their UID directive.

UID stands for “Unique Identification.” As defined by the DoD, “Unique IDentification is a set of data for tangible assets that is globally unique and unambiguous, ensures data integrity and data quality throughout life, and supports multi-faceted business applications and users.”

Dapra Marking has been supplying DPM solutions for more than 30 years. Initial marking requirements were for unique serial numbers and date codes to be permanently marked on the component for traceability throughout the life cycle of the component. With the introduction of the 2D Data Matrix code, substantial data can be stored and encoded within a smaller footprint than in the past. To accommodate the growth of 2D technology, Dapra has expanded its product offering to encompass custom-engineered and turnkey solutions for dot peen and laser marking. These systems include appropriate verification and reading technology required to meet the standards of various industries, including DoD MIL-STD-130M.

DoD / UID Direct Part Marking (DPM):

- Fighter jet and tank components

- Parts for military vehicles, ammunitions, firearms, etc.